Truss Manufacturing Time Standards (Man-Minutes)

These Work Minute / R.E. / S.U. time standards have been tested, validated, and used inside 100+ wood truss operations, giving owners and managers a reliable way to:

-

Price work accurately

-

Schedule production realistically

-

Measure productivity objectively

-

Protect margins before problems show up on the P&L

The result is clarity—knowing exactly how long work should take, what it should cost, and where performance breaks down.

TDC Time Standards are available with or without an onsite consultation, allowing companies to choose the level of support that fits their needs—while still gaining access to proven, real-world benchmarks that actually work.

Pricing the Right Jobs Makes More Money —

Pricing the Right Jobs Makes More Money — Before You Ever Build Them

Most component manufacturers don’t lose money because they can’t build trusses.

They lose money because they price the wrong work—and don’t discover it until capacity is gone and margins are already damaged.

Traditional pricing formulas hide the truth.

They blend labor and material into a single number and tell you nothing about how hard your manufacturing resources are actually working for the return you’re getting.

TDC’s Labor Time Standard Pricing Formula fixes that.

By pricing jobs using work minutes (R.E. / S.U.), you instantly see your gross-margin dollars per estimated hour—not just a percentage that looks good on paper.

That single shift creates immediate clarity:

-

You instantly spot high dollar-per-hour jobs

-

You expose low-return work that consumes capacity but doesn’t pay for it

-

You stop filling your plant with orders that look busy but deliver weak profits

At a glance, you know which jobs deserve your tables—and which ones you should confidently let your competitors take.

This isn’t just better pricing.

It’s better decision-making.

You stop guessing.

You effectively give your company an hourly raise simply by choosing the right work to run through your plant.

Over time, that leads to:

-

Higher margin dollars per hour

-

Better use of manufacturing capacity

-

Stronger net profits—without increasing volume or stress

This is why companies using TDC time-based pricing consistently outperform those relying on traditional formulas.

For a deeper explanation, see the LinkedIn article: Component Manufacturing Pricing Formula to Make More Net Profit.

Eliminate Scheduling Problems Using Proper Time Standards

For many companies, scheduling feels impossible to control.

And it’s not a coincidence that those same companies usually struggle with margins.

Operations that schedule well are almost always the ones with the best net profits.

Why? Because accurate time standards allow you to:

-

Protect capacity for higher-margin rush orders

-

Flow lower-priority work efficiently

-

Reduce chaos, rework, and constant firefighting

If scheduling is a constant headache in your operation, the root cause is almost always inaccurate or missing time standards.

There are four common causes—and proven solutions—to fixing it.

See the LinkedIn article: Scheduling a Problem Within Your Company?

(TDC published article)

Using Proper Time Standards, you can Gain More than 10% in Labor Savings Through a Proven Method Endorsed by Scott Arquilla

For years, TDC has promoted the idea of using reliable estimated work minutes (R.E., S.U., Man-Minutes) for scheduling, pricing, and understanding true labor efficiencies. The most important aspect of properly developed work minutes is that you can create a short-scheduling time standards system. In essence, you show the workers, such as a workstation assembly crew, how much time it should take for them to complete their task, like a batch run. Then periodically, such as every other hour, their progress of actual versus estimated can be checked.

And, it’s not only me who is a firm believer in this method. Retired component manufacturer, and former WTCA President, Scott Arquilla is not shy about sharing his thoughts on the matter. In fact, he was co-author on an article almost twenty years ago on the subject: Houlihan: Recipe for Production Success by Libby Walters with Scott Arquilla, SBC Magazine, December 2004.

Scott took the time to speak with me at the 2023 BCMC to show gratitude for my efforts to help CMs and to express his encouragement that I keep preaching the benefits of the Houlihan methodology. Here, I’m pleased to share this testimonial from Scott on how effective this scheduling process is in the very real world of wood truss component manufacturing.

Scott took the time to speak with me at the 2023 BCMC to show gratitude for my efforts to help CMs and to express his encouragement that I keep preaching the benefits of the Houlihan methodology. Here, I’m pleased to share this testimonial from Scott on how effective this scheduling process is in the very real world of wood truss component manufacturing.

An Endorsement of the Houlihan Method of Realistic Expectations for Component Plants

By Scott Arquilla, Retired

I strongly endorse the use of the Houlihan Method for any component plant. It saved our company well over 10% in ‘pre-Houlihan’ annual labor costs for years.”

Full article on LinkedIn Better Than 10% Labor Savings Proven Method Endorsement by Scott Arquilla.

For more than twenty years, TDC has built and refined true labor time standards—work minutes, R.E., S.U., and man-minutes—using proper industrial engineering motion and time study methods.

This work is difficult, time-intensive, and never finished. Accurate time standards must be continuously validated, adjusted, and updated as materials, equipment, layouts, and workflows change. There are no shortcuts.

And to be clear: board-foot formulas and piece counts are not substitutes for properly developed work minutes in wood truss manufacturing. They mask real labor demand, distort pricing, and lead to poor scheduling and margin erosion.

Only true work-minute standards show how hard your manufacturing resources are actually working—and what each job is really earning you.

That is why companies relying on real time standards consistently outperform those using estimates, averages, or simplified formulas.

Time Standards Labor Estimations

√ Costing

√ Scheduling

√ Station Efficiency Ratings (Productivity)

√ Incentive Programs Using Efficiency Ratings

√ Pricing based on Reliable Labor Time Units.

_

Keith Myers of Woodhaven Lumber & Millwork

Lakewood, NJ

“BF seems to be the national standard for truss manufacturers mainly because that’s what the software has typically reported. Additionally, lumber yards always deal with BF. The truth is, we pay labor dollars for time, not pieces, nor BF. Whether I have a 2x10 or a 2x4 wedge, it takes the same amount of time to pick it up and install it into a truss. When attempting to build a pricing model within a costing program, one needs lumber, plates, and labor. Labor is a measure of time, which is paid in dollars. Those dollars can be calculated easily with the proper data. It takes more time to build a 32-foot attic truss than a 32-foot fink, and the costing model should reflect that fact.”

I asked Keith, “Are you using the time standards for MM that I provided you during the consultation and, if so, how have they worked out for you compared to BF?” Keith replied, “Your time standards are perfect. They are far more accurate than BF. We are much more comfortable with the MM for the estimation of labor for both the pricing and shop scheduling. BF is just too unreliable for our needs. No more educated guessing for our costing and pricing.”

120+ Different Time Elements to Choose for Differing Conditions

Kylmala Truss

Keith Kylmala – Owner

Saginaw, MN

"We are an Alpine customer, and all I can say is Todd’s time standards are scary accurate! Once we set up the labor configuration file based on our equipment and practices, our truss software estimates the labor time and cost in a spectacularly accurate way. We love how many options there are to choose from with Todd’s time standards labor document. No more educated guessing for our costing and pricing.”

- Refined for over 20 years of consulting services

- All time elements are based on minutes – May use as units of R.E. or S.U.

- All time elements adjust and account for “normal” staffing

- All based on equipment and type of materials

- Derived from proper industrial engineering practices of time and motion studies

- All types of saws and build tables with/without automation with expected results

_

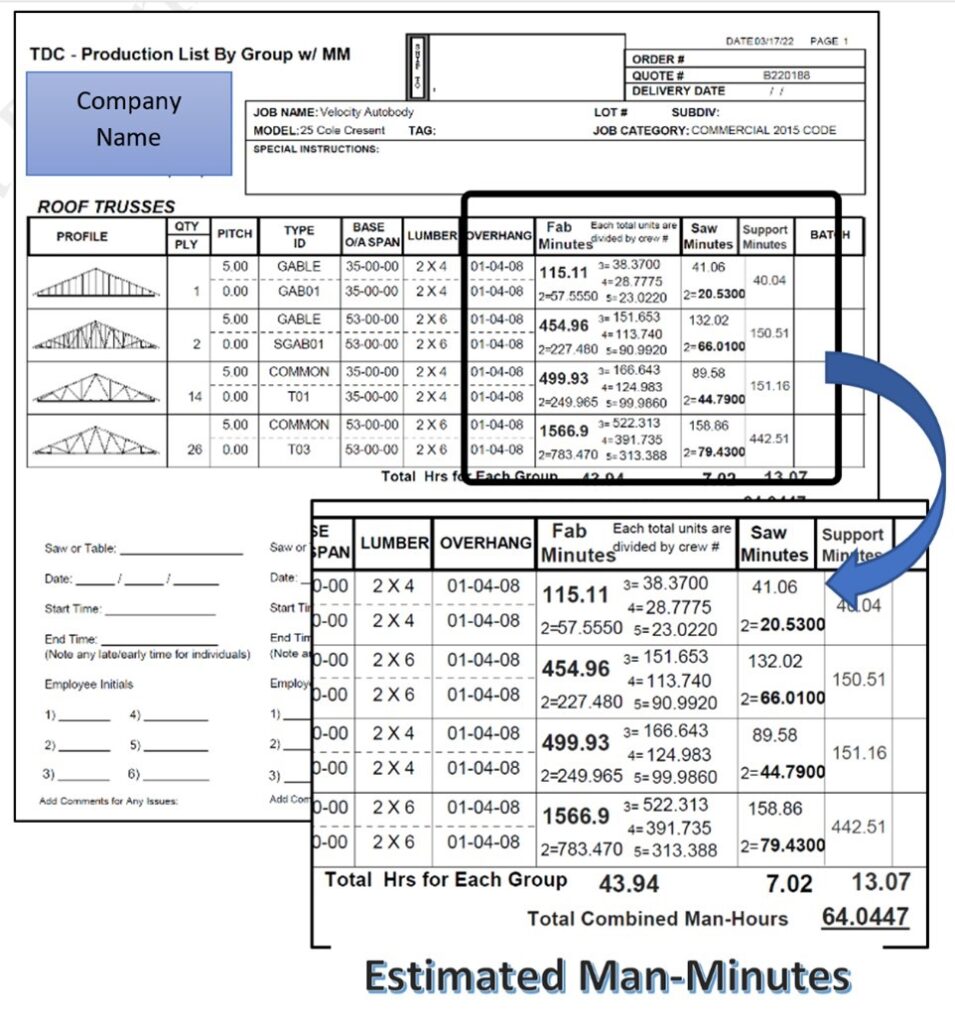

Show the estimated time for each truss, and the batch, for the tables and saw.

Shown example below displays the time for the table per number of assemblers.

By the way, you can use TDC time standards alongside your current method, such as BF, and prove to yourself how much more accurate TDC time standards are using work-minutes (man-minutes estimation) for comparison.

Time Standards Offered With or Without

Consultation Services – Contact Todd for Details.

Leduc Truss Inc.

Gordon Tober, Co-Owner, and GM

Leduc, AB Canada

"The one area that started this process was our desire to refine our estimating techniques. Our equipment had changed dramatically over the years but our bidding time estimations had not been properly updated. Todd provided us with time standards that were specific to the equipment that we use. This information allowed us to estimate our jobs with a dramatically increased level of accuracy on each project, regardless of its level of complexity. The time standards also gave us the information to measure our production and establish target output for each workstation in our shop."

Over a 120 factors to choose from that can be inputted into MiTek MVP™ and also

for the MBA™ for truss labor estimations.

Do you have MiTek MVP™ in your truss manufacturing but have failed to create a reliable labor estimation in the labor estimation setup? Do you need the MVP™ program to be more effective for estimating the labor man-hours for scheduling and efficiency ratings? Let TDC help you! My time standards have been created and refined over the past 20 years to adjust for most of the manufacturing equipment types and lumber material sizes.

The Alpine™ program and other truss labor estimating programs can also use these same factors.

TDC can either provide while at your location or simply email you the time (labor) standards for you to input yourself.

See helpful article: Truss Labor Time Standards for MiTek MVP™ and Other Programs

Read more reviews of clients' experiences with TDC here

Todd Drummond Consulting LLC is an independent consulting service and is not affiliated with the MiTek or the Alpine (ITW) Corporations. Alpine is both a copyright protected and registered trademark of the ITW Corporation. MiTek MVP and MBA are registered trademarks of the MiTek Corporation. TDC time standards services apply only to the labor estimation and not to any other aspects of the truss estimation or labor tracking programs.

Todd Drummond Consulting LLC

Copyrights © 2002-2026 Todd-Drummond.com

Todd Drummond Consulting LLC

Copyrights © 2002 - 2026 Todd-Drummond.com

(603) 748-1051

todd@todd-drummond.com

www.linkedin.com/in/todrummond