Truss Manufacturing Time Standards

TDC has been perfecting the wood truss labor time standards (work minutes, R.E. or S.U.) that have been refined over two decades and used in over a hundred different companies. Time Standards Offered With or Without Consultation Services.

(Related Article Link)

A-1 Industries – Leader in Wood Truss Industries Uses Industrial Engineering Practices.

How One Wood Truss Industry Leader Uses Industrial Engineering Practices of Work Minutes to Excel

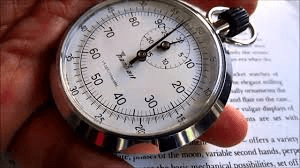

Better Than 10% Labor Savings Proven Method Endorsement by Scott Arquilla

For years, TDC has promoted the idea of using reliable estimated work minutes (R.E., S.U., Man-Minutes) for scheduling, pricing, and understanding true labor efficiencies. The most important aspect of properly developed work minutes is that you can create a short-scheduling time standards system. In essence, you show the workers, such as a workstation assembly crew, how much time it should take for them to complete their task, like a batch run. Then periodically, such as every other hour, their progress of actual versus estimated can be checked.

And, it’s not only me who is a firm believer in this method. Retired component manufacturer, and former WTCA President, Scott Arquilla is not shy about sharing his thoughts on the matter. In fact, he was co-author on an article almost twenty years ago on the subject: Houlihan: Recipe for Production Success by Libby Walters with Scott Arquilla, SBC Magazine, December 2004.

Scott took the time to speak with me at the 2023 BCMC to show gratitude for my efforts to help CMs and to express his encouragement that I keep preaching the benefits of the Houlihan methodology. Here, I’m pleased to share this testimonial from Scott on how effective this scheduling process is in the very real world of wood truss component manufacturing.

-----------------------------------------------------

An Endorsement of the Houlihan Method of Realistic Expectations for Component Plants

An Endorsement of the Houlihan Method of Realistic Expectations for Component Plants

By Scott Arquilla, Retired

(former VP, Best Homes, Inc., Hazel Crest, IL and 2003 WTCA President)

“My family started Best Homes, Inc. (roof and floor trusses and wall panels) in 1957 as a supplier to our family homebuilding business, which was a much larger operation. I left the banking business in 1989 and joined the business. Given my background in Finance, I always looked at the numbers. Throughout my early years, it was difficult to put a handle on the differences between actual vs. bid labor costs and why they often varied monthly and annually. Being located in the Chicago suburbs, we were a Union shop. It seemed we underestimated the labor in difficult jobs and overestimated the labor on easy jobs. In the late 1990s, I started hearing about the Houlihan System (short scheduled time standards work scheduling popularized by John Houlihan, an Industrial Engineer) at WTCA Board meeting ‘social’ events. All I heard were their successes. I was sold, and we took the first steps to fully manage our shop labor.

While John Houlihan was basically retired, we employed his co-worker and successor, Don Ullmer, who spent a week at our plant. Don provided a preview of potential labor savings if we adopted Realistic Expectations (R.E.) labor estimation. Don suggested that we could recoup our initial $75,000 investment by the end of year 2 if we went forward. A few months later, Don and his assistant, Frank Zientarski, were in our plant for about twelve weeks, six weeks each, for analysis and then system implementation of every movement of personnel and lumber. It was a tough adoption as the men didn’t really like someone looking over their shoulders, and the Carpenters Union had strong questions.

But, after the initial three months and another month of working out the kinks, the system was fully in place. Most importantly, hourly reporting of work completed was submitted, and daily meetings of foremen were held to analyze daily work ‘produced’ or finished and labor hours expended. Scheduling of work was far easier because we knew what we could produce given the personnel we had. By reviewing hourly and daily production, bottlenecks were addressed and resolved quickly. Our estimating system incorporated this method, and job R.E.’s were a part of the cutting and build sheets. Certain jobs were priced higher because of the number of setup changes. Easier jobs were priced lower because of less difficulty. All in all, it made our plant run much smoother.

I strongly endorse the use of the Houlihan Method for any component plant. It saved our company well over 10% in ‘pre-Houlihan’ annual labor costs for years.”

-----------------------------------------------------

For over twenty years, TDC has developed proper time standards (work minutes, R.E., S.U., Man-Minutes.) using proper industrial engineering practices of motion and time studies. This process is not easy, requires a great deal of time, and constantly needs updating. I can tell you emphatically that board foot units and piece count do not work as an alternative to properly developed work minutes for wood roof truss manufacturing.

For over twenty years, TDC has developed proper time standards (work minutes, R.E., S.U., Man-Minutes.) using proper industrial engineering practices of motion and time studies. This process is not easy, requires a great deal of time, and constantly needs updating. I can tell you emphatically that board foot units and piece count do not work as an alternative to properly developed work minutes for wood roof truss manufacturing.

Time Standards Labor Estimations

√ Costing

√ Scheduling

√ Station Efficiency Ratings (Productivity)

√ Incentive Programs Using Efficiency Ratings

√ Pricing based on Reliable Labor Time Units.

_

Helpful article: Truss Labor Time Standards for MiTek MVP™ and Other Programs (Click Link)

Keith Myers of Woodhaven Lumber & Millwork

Lakewood, NJ

“BF seems to be the national standard for truss manufacturers mainly because that’s what the software has typically reported. Additionally, lumber yards always deal with BF. The truth is, we pay labor dollars for time, not pieces, nor BF. Whether I have a 2x10 or a 2x4 wedge, it takes the same amount of time to pick it up and install it into a truss. When attempting to build a pricing model within a costing program, one needs lumber, plates, and labor. Labor is a measure of time, which is paid in dollars. Those dollars can be calculated easily with the proper data. It takes more time to build a 32-foot attic truss than a 32-foot fink, and the costing model should reflect that fact.”

I asked Keith, “Are you using the time standards for MM that I provided you during the consultation and, if so, how have they worked out for you compared to BF?” Keith replied, “Your time standards are perfect. They are far more accurate than BF. We are much more comfortable with the MM for the estimation of labor for both the pricing and shop scheduling. BF is just too unreliable for our needs. No more educated guessing for our costing and pricing.”

120+ Different Time Elements to Choose for Differing Conditions

Kylmala Truss

Keith Kylmala – Owner

Saginaw, MN

"We are an Alpine customer, and all I can say is Todd’s time standards are scary accurate! Once we set up the labor configuration file based on our equipment and practices, our truss software estimates the labor time and cost in a spectacularly accurate way. We love how many options there are to choose from with Todd’s time standards labor document. No more educated guessing for our costing and pricing.”

- Refined for over 20 years of consulting services

- All time elements are based on minutes – May use as units of R.E. or S.U.

- All time elements adjust and account for “normal” staffing

- All based on equipment and type of materials

- Derived from proper industrial engineering practices of time and motion studies

- All types of saws and build tables with/without automation with expected results

_

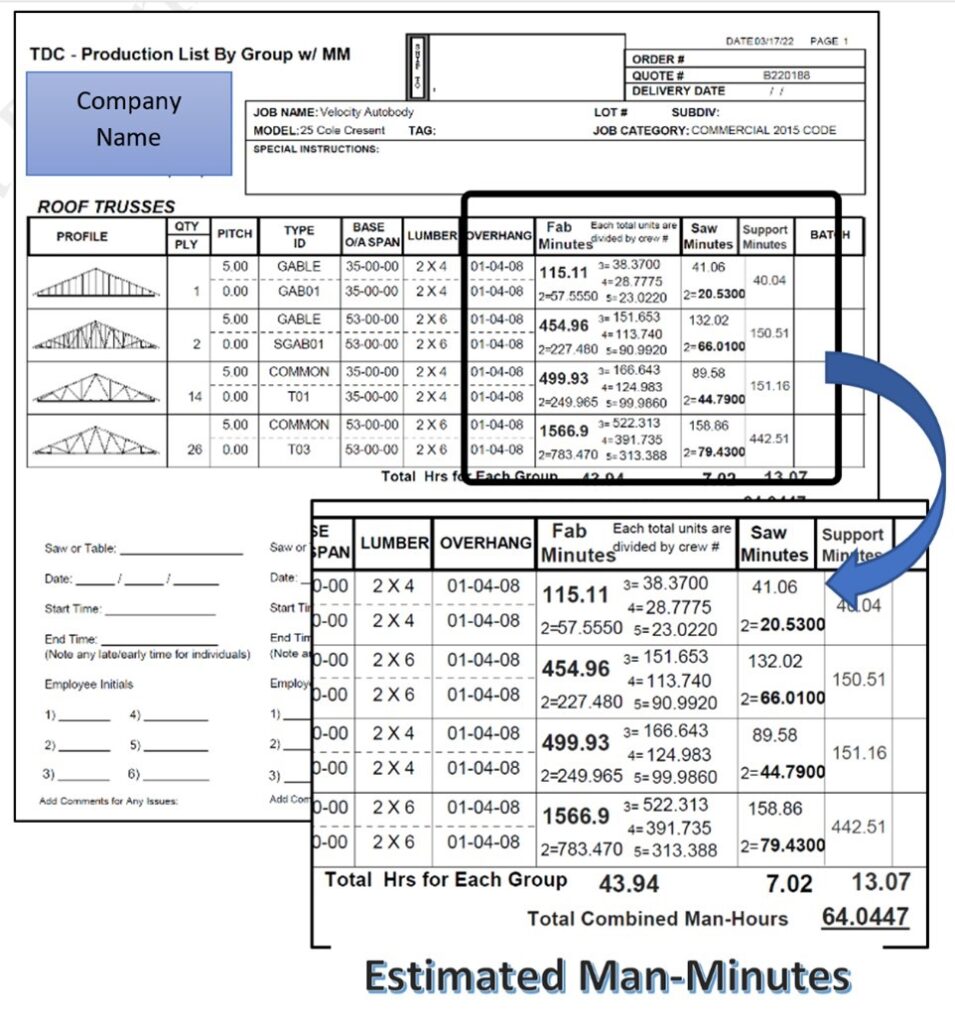

Show the estimated time for each truss, and the batch, for the tables and saw.

Shown example below displays the time for the table per number of assemblers.

By the way, you can use TDC time standards alongside your current method, such as BF, and prove to yourself how much more accurate TDC time standards are using work-minutes (man-minutes estimation) for comparison.

Time Standards Offered With or Without

Consultation Services – Contact Todd for Details.

Leduc Truss Inc.

Gordon Tober, Co-Owner, and GM

Leduc, AB Canada

"The one area that started this process was our desire to refine our estimating techniques. Our equipment had changed dramatically over the years but our bidding time estimations had not been properly updated. Todd provided us with time standards that were specific to the equipment that we use. This information allowed us to estimate our jobs with a dramatically increased level of accuracy on each project, regardless of its level of complexity. The time standards also gave us the information to measure our production and establish target output for each workstation in our shop."

Over a 120 factors to choose from that can be inputted into MiTek MVP™ and also

for the MBA™ for truss labor estimations.

Do you have MiTek MVP™ in your truss manufacturing but have failed to create a reliable labor estimation in the labor estimation setup? Do you need the MVP™ program to be more effective for estimating the labor man-hours for scheduling and efficiency ratings? Let TDC help you! My time standards have been created and refined over the past 20 years to adjust for most of the manufacturing equipment types and lumber material sizes.

The Alpine™ program and other truss labor estimating programs can also use these same factors.

TDC can either provide while at your location or simply email you the time (labor) standards for you to input yourself.

See helpful article: Truss Labor Time Standards for MiTek MVP™ and Other Programs

Read more reviews of clients' experiences with TDC here

Todd Drummond Consulting LLC is an independent consulting service and is not affiliated with the MiTek or the Alpine (ITW) Corporations. Alpine is both a copyright protected and registered trademark of the ITW Corporation. MiTek MVP and MBA are registered trademarks of the MiTek Corporation. TDC time standards services apply only to the labor estimation and not to any other aspects of the truss estimation or labor tracking programs.

Todd Drummond Consulting LLC

Copyrights © 2002-2023 Todd-Drummond.com

Todd Drummond Consulting LLC

Copyrights © 2002 - 2021 Todd-Drummond.com

(603) 748-1051

todd@todd-drummond.com

www.linkedin.com/in/todrummond