LinkedIn Articles by TDC

Articles published on LinkedIn – New One Each Month

LinkedIn Profile to Follow: https://www.linkedin.com/in/todd-drummond-5ab0a823

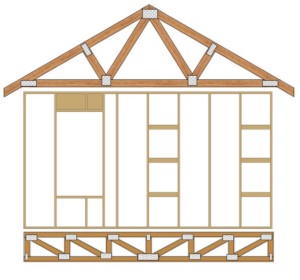

Possible 30 Days Savings for the Home Builder Using Wall Panels

Possible 30 Days Savings for the Home Builder Using Wall Panels

Did you know that, even though setting wall panels saves an average of eleven days compared to traditional stick-framing of walls, the overall home completion can have an average savings of 30 days when wall panels have been used? For the home builders, every day a home is completed sooner can be a savings of $250 to $1,000 per day

Read the full article on LinkedIn: https://lnkd.in/eDeA6VB

Small Investments Can Garner Huge Gains for Productivity for Your Sales Team

Truss & Wall Panel Component, Modular Homes, LBM and Home Builders. Now it is time to offer real solutions to help your company improve productivity and reduces costly errors for your sales team and also all of the other critical areas of your business. The simple fact is most companies’ sales processes have not evolved for decades. Therefore, the sales and management teams are working far harder than they need to be to get the work done quickly and without any errors. Two critical constraints are causing all kinds of lost productivity. (Click Here for Linked Article)

Quote Truss and Wall Panel Project 5-10x Faster than Component Design Programs - One excellent way to improve the productivity of the design group is to have them not use the design program for every project for job estimation.

An Effective Productivity Incentive Program for Truss Manufacturing

It is possible to give your shop employees a raise and actually achieve more capacity through greater productivity and make more net profit for your company by implementing an effective productivity incentive program. However, most of the incentive programs (IP) that are touted in the component industry fail to achieve the desired results. (Click Here for LinkedIn Article)

The Drummond Short Schedule Time-Standard System

The Drummond Short Schedule Time-Standard System

Many of the elderly people in our industry have heard of the “Houlihan System.” Way back in the ‘70s, John Houlihan (and later, Don Ullmer and Frank Zientarski, industrial engineers [IE]), helped bring attention to what many considered a new system. This Houlihan system proved that truss manufacturers would have noticeable and worthwhile gains in productivity when properly applied (explained in detail below). What is the Houlihan Drummond System? Well, quite simply, John—and yours truly—simply added our names to a method of applying short scheduling measurement using time standards based on man-minutes for truss manufacturing. (Click Here for LinkedIn Article)

McCabe Lumber

Joe Tepe –Components – Division Manager, Co-Owner

Loveland, Ohio

McCabe

In recent years, the market for component manufacturing businesses has changed drastically. Our industry has become extremely competitive. The drop in construction has caused manufacturers to reduce prices as far as possible in order to “get the job.” During this time, we are forced to question our estimating techniques. We believe that a critical key to success is the ability to identify our true cost on every job that we estimate. We have to be aware of the point at which the job is no longer profitable.

Todd provided us with time standards which were specific to the equipment that we use. This information allowed us to estimate our jobs with a dramatically increased level of accuracy on each project, regardless of its level of complexity. The time standards also gave us the information to measure our production and establish target output for each workstation in our shop.

Todd also offered suggestions for lean manufacturing practices, marketing, quality control, production, and design incentives. We continue to implement his ideas, which have received positive feedback from our customers. Each has resulted in improvements to our operations.

I recommend Todd’s consultation to any truss manufacturer, even during this difficult market. The expense of the consult was money well spent in improving our profitability.

Articles published on LinkedIn – New One Each Month

LinkedIn Profile to Follow: https://www.linkedin.com/in/todd-drummond-5ab0a823

Todd Drummond Consulting LLC

Copyrights © 2002-2023 Todd-Drummond.com

Todd Drummond Consulting LLC

Copyrights © 2002 - 2021 Todd-Drummond.com

(603) 748-1051

todd@todd-drummond.com

www.linkedin.com/in/todrummond